Process

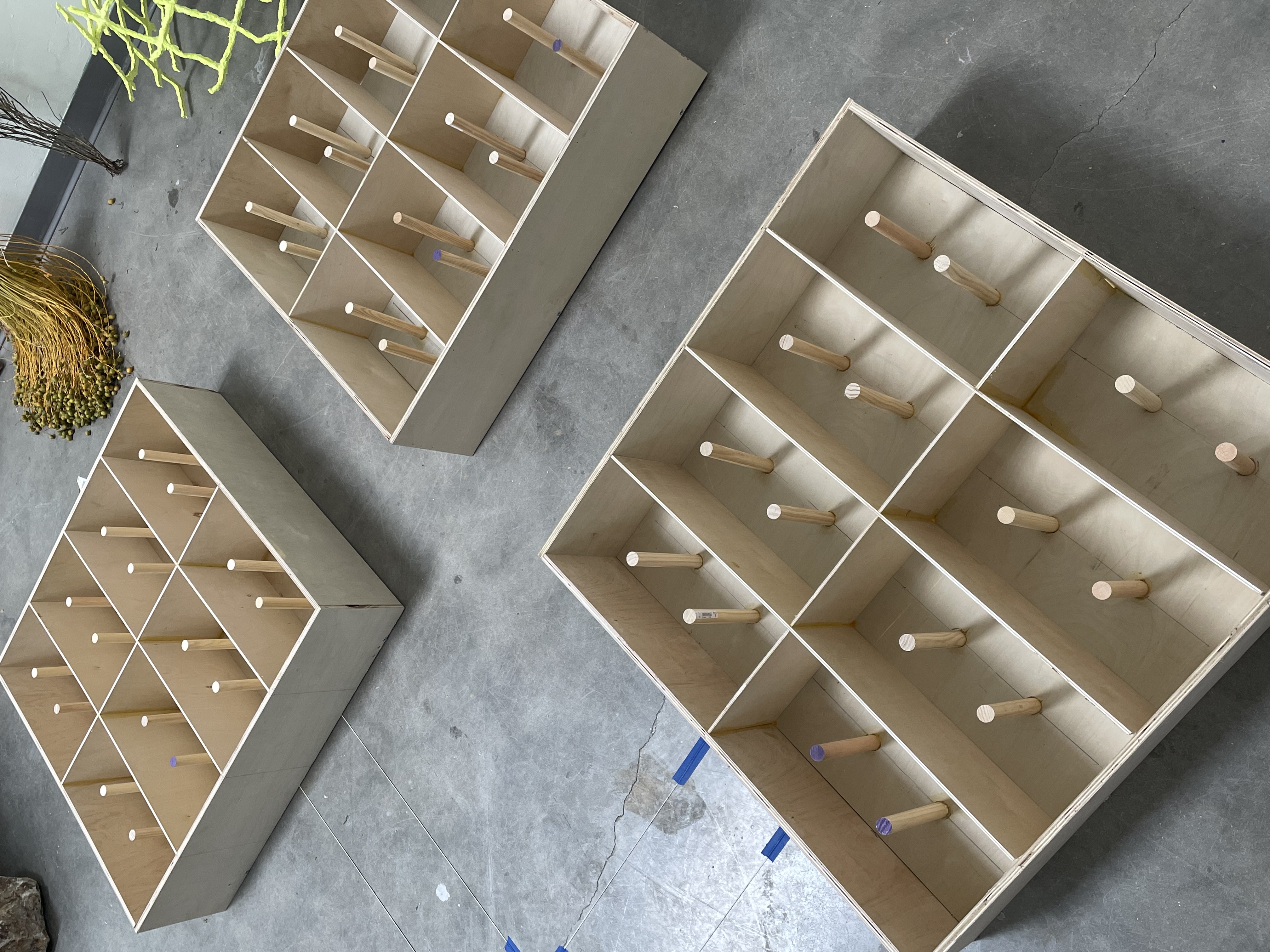

Wooden mold construction: Three wooden molds were fabricated to produce the 16” x 8” x 8” blocks. Each brick has two 7/8” dowels to provide space for the metal armature. The molds eventually were adapted to promote oxygen flow by perferating the bottom.

Growing: Living mycelium material, purchased from Grow.Bio, is mixed with flour and packed into the wooden molds and covered with a perforated plastic film. The mycelium is left to grow in the molds for five to six days.

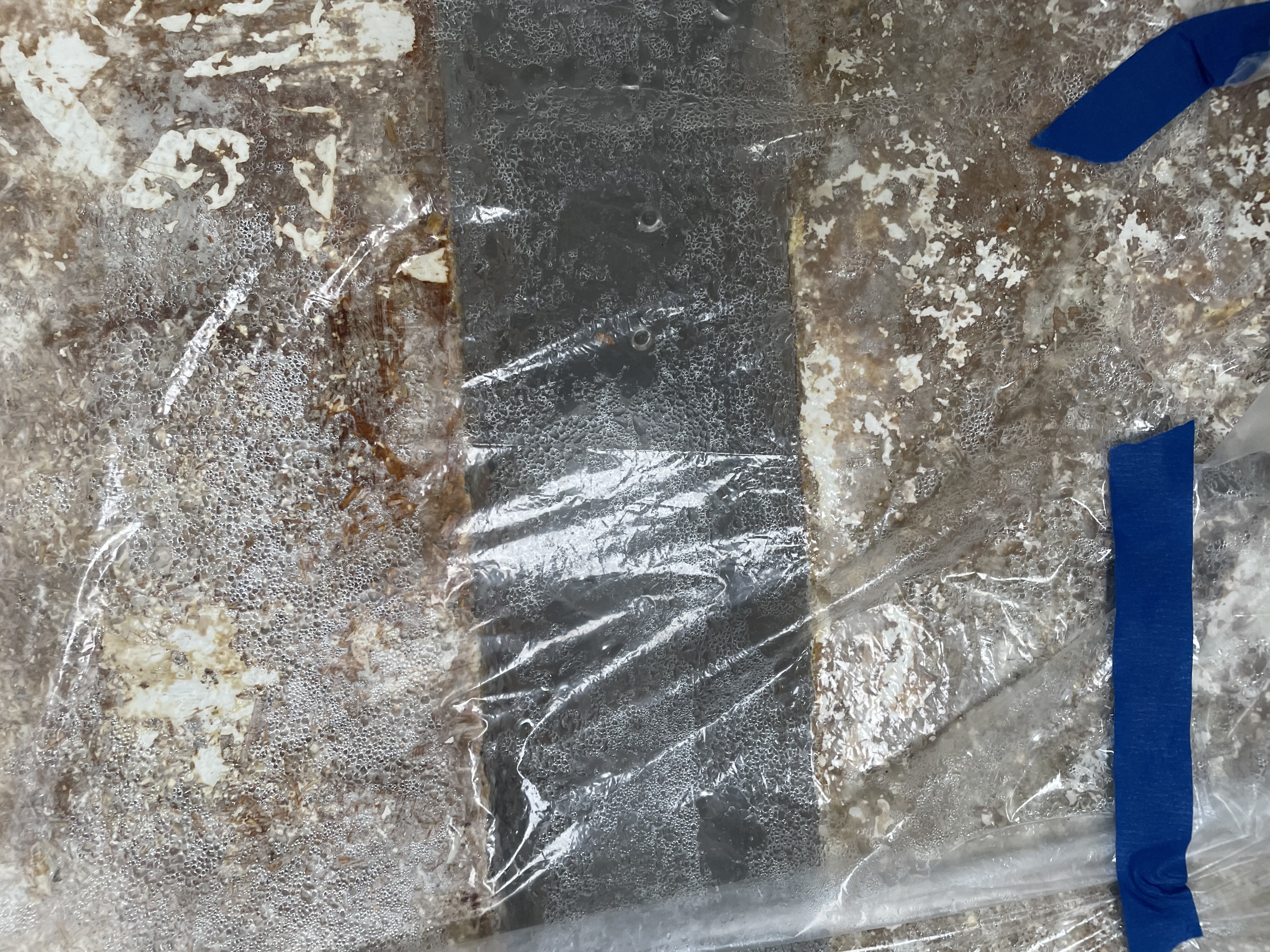

Overgrowth: After the bricks are removed from the molds, they are wrapped loosely in plastic and given time to continue their growth. During this time, a thick film of mycelium develops over the brick, healing any damage that resulted from its removal from the molds, and solidifying the outer walls. During this process, various colors and patterns begin to emerge on the surfaces of the blocks. The bricks were left for various amounts of time.

Drying: The final step in the mycelial brick production is to dry the brick to stop the mycelium growth. However, under the right circumstances, the mycelium continued to grow, developing vibrant colors across the surface of the bricks and sprouting fruiting bodies.

Photos: lydia see and Claire Fall Blanchette